Automotive is among of the largest producers of components made from die-cast in Malaysia manufacturing companies relying on this process to produce vital vehicle components. Die-cast parts made of zinc and aluminum are commonly used in engine blocks, structural brackets, transmission housings, and lightweight frames, contributing to overall performance of vehicles and their efficiency. In the current global auto industry, which shifts towards electric vehicles, the need for precise die-casting components has risen significantly. Die-casting firms in Malaysia have responded through the development of specialized components like battery casings, motor housings, and cooling systems specifically for hybrid and electric vehicles. Incorporating advanced casting technologies, such as vacuum die casting as well as high-pressure die casting, ensures that you can make high-strength and light-weight components that are essential in modern vehicles. With Malaysia playing a key role in the distribution chain, locally-owned casting companies are constantly innovating to meet the stringent requirements of automakers around the world.

The electronics and telecoms industry within Malaysia also benefit greatly from die casting, as it allows the production of intricate metal parts with excellent thermal and electrical conductivity. Malaysia is a leading exporter of electronic components, providing global brands with die-cast enclosures and heat sinks connectors, shielding casings. These components are essential for ensuring the efficiency and longevity of electronic devices including smartphones computer systems, laptops, communications servers and data storage equipment. As technology advances, die-casting firms located in Malaysia focus on increasing the properties of materials, decreasing production costs, and improving the longevity of their products. The need for light and resistant to heat has led to the development of aluminum and magnesium alloys, which offer better performance and durability for electronics of the highest quality. With the rise of 5G technology and the increasing reliance on electronic gadgets, Malaysia's die casting sector is predicted to witness continued growth in this sector.

Sustainability has been a primary focus in Malaysia's die-casting industry in order to reduce environmental impact while maintaining high production standards. Reusing and recycling metals are a common practice in this industry, which helps to reduce waste and lower cost of production. A lot of manufacturers have implemented efficient and energy-efficient casting techniques in order to lower carbon emissions. Sustainable manufacturing is resulting in the acceptance of greener processes including vacuum casting and low-pressure casting that reduce waste of materials and increase the quality of finished products. Using organic coatings and other surface treatments can further increase the lifespan of die-cast components without harmful impacts on the environment. With the shift of global industry towards greener production methods, Malaysian die-casting companies are setting themselves up as the pioneers in the field of green metal casting. Government support of green initiatives as well as industry certifications encourages businesses to adopt environmentally responsible practices while remaining competitive in the international market. To get new details kindly check out www.senadiecasting.com.my/

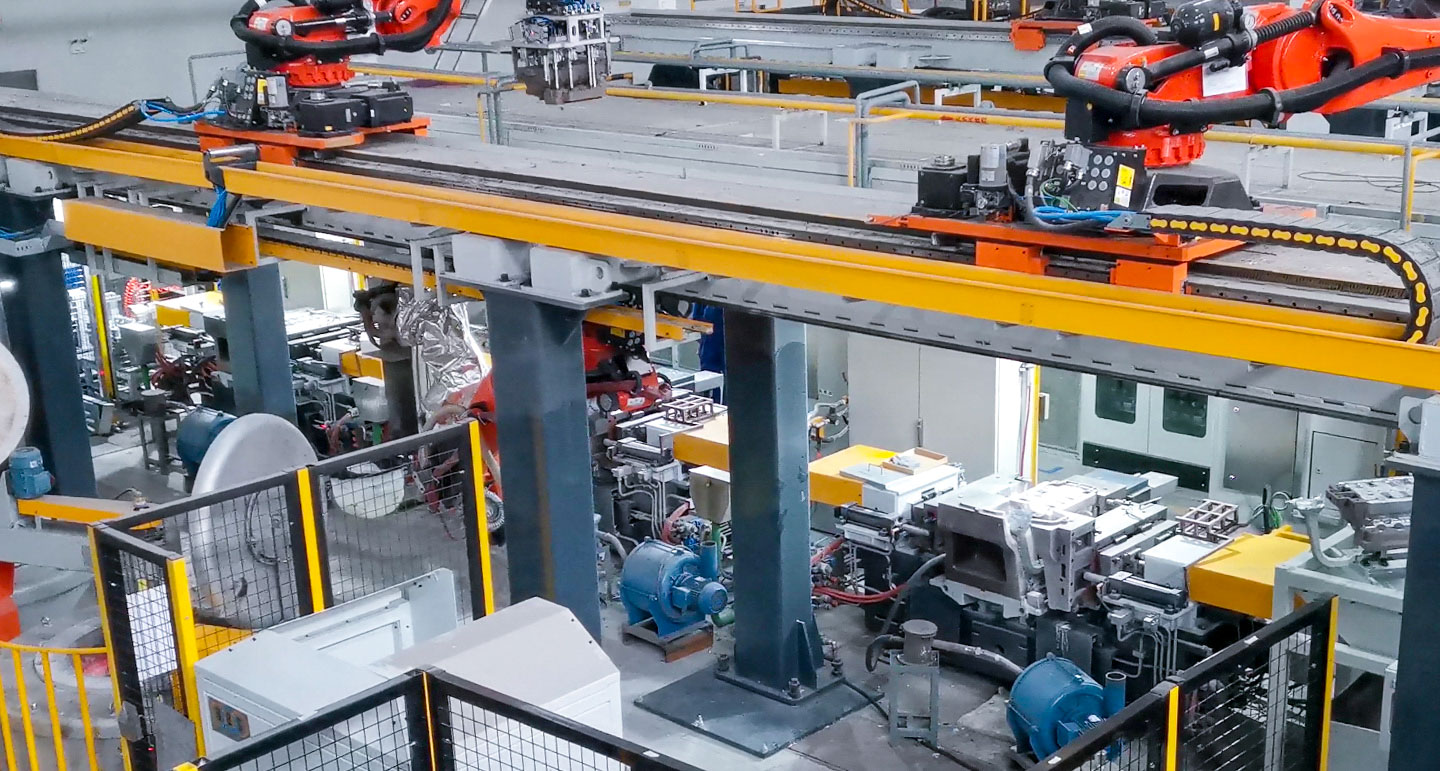

Continuous advancements in the design of molds and tools has significantly enhanced the efficiency and quality of die-casting Malaysia. Quality molds are vital for making components that are free of defects, and the manufacturers are utilizing computer-aided design and computer-aided manufacturing software to increase the accuracy and precision of the molds they use. Simulation software allows engineers to identify potential problems and improve the parameters of casting before beginning production which reduces waste material and improving product consistency. Utilizing robotics and automated molding process has also streamlined the manufacturing, which allows producers to make large amounts of components without human intervention. These technological innovations have not only increased productivity but also reduced costs which makes Malaysian die-casting companies more competitive on the global market. As industries demand higher precision and efficiency, continued investment in mold design and the tooling process will be vital to maintaining the development of the industry.

As we look to the future, Malaysia's die-casting industry will likely to witness significant expansion, driven by sustainability, innovation as well as a growing demand for precision metal components. The government and industry leaders collaborate to improve efforts to research and develop and encourage the use of advanced materials and new casting techniques. The workforce training program is designed to equip workers with the skills needed to operate modern die-casting machinery and automated systems. Since industries like electric automobiles, renewable energy and smart technology continue to increase, Malaysia's die-casting business is well placed to satisfy the growing demand for metal components that are high-performing. A strong infrastructure for manufacturing in the country as well as its commitment to sustainable development and technological innovation is a guarantee that Malaysia continues to be a leading actor in the world die-casting industry. Through continuous improvement and strategic investments, the sector continues to propel economic growth while preserving its status as an institution of excellence in precision manufacturing.